BBP Agreement Term

A multifeedstock biorefinery is being planned for the Southeastern Hub within a major chemical complex in the Vale do Paraiba, Sao Paulo. This co-siting alternative will reduce CAPEX and time to market, and will also leverage on existing rail and truck facilities at the chemical plant for inbound feedstocks, and outbound of BioJetfuel to major airport hubs as well as of renewable chemicals local markets or for export through the Port of Santos in Sao Paulo.

A multifeedstock biorefinery is being planned for the Southeastern Hub within a major chemical complex in the Vale do Paraiba, Sao Paulo. This co-siting alternative will reduce CAPEX and time to market, and will also leverage on existing rail and truck facilities at the chemical plant for inbound feedstocks, and outbound of BioJetfuel to major airport hubs as well as of renewable chemicals local markets or for export through the Port of Santos in Sao Paulo.

While awaiting the scaling up of the major agricultural crops, the Platform at this initial stage will rely on the following supply chains:

a) Animal fat

b) Used cooking oil from Paraíba valley

c) Macaúba oil from natural maciços in Dores do Indaiá, Minas Gerais.

d) Jatropha oil from Minas Gerais, Espirito Santo, Sao Paulo, Rio de Janeiro and Parana

e) Camelina oil from the soy regions of Paraná, Mato Grosso, Mato Grosso do Sul and Rio Grande so Sul,

The biorefinery will have a start up nominal plant capacity of 150.000 t/yr, to be implemented by 2015/2016. Additional plant expansion capacity to 300.000 t/yr is planned for commissioning by 2018/2019.

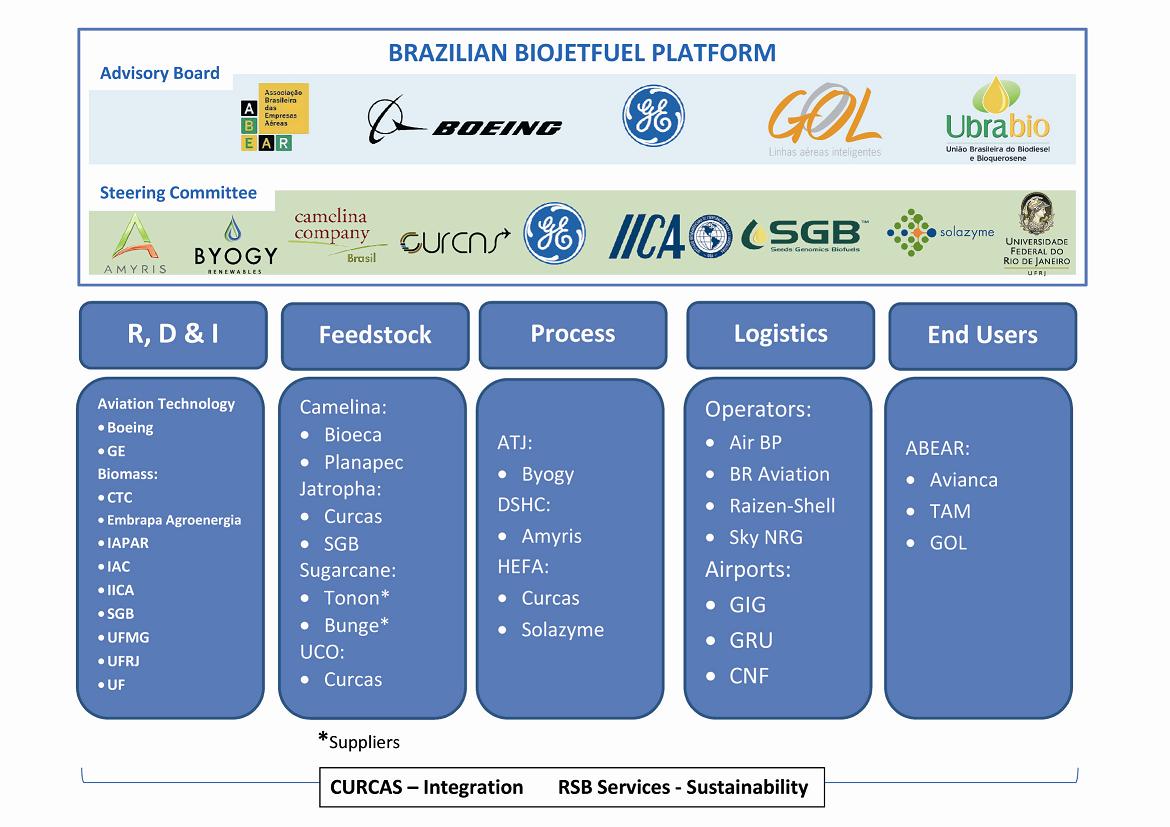

The Brazilian Biojetfuel Platform was formally structured on August 8th, 2013 as an open, collaborative platform to bring together key stakeholders to promote the implementation of a highly integrated biojetfuel and renewable value chain, "from R&D to the wing", to fill in the gaps identified by the Sustainable Alternative Biojetfuel study sponsored by Boeing, Fapesp and Embraer.

A Governance body with an Advisory Board and Steering Committee was elected to promote the necessary actions to elaborate a Road Map for the segment.

The Initiative intends to be a multi feedstock, multi process platform integrating the existing initiatives for feedstock R & D, the Amyris DSHC value chain in Brotas -SP, the Solazyme plant in Orindiúva – SP, the Byogy ATJ projects and the HEFA Curcas biorefinery in Guaratinguetá – SP, and Aviation segment technologies from Boeing and GE.

- Bring together the stakeholders for integration, optimization and segment coordination.

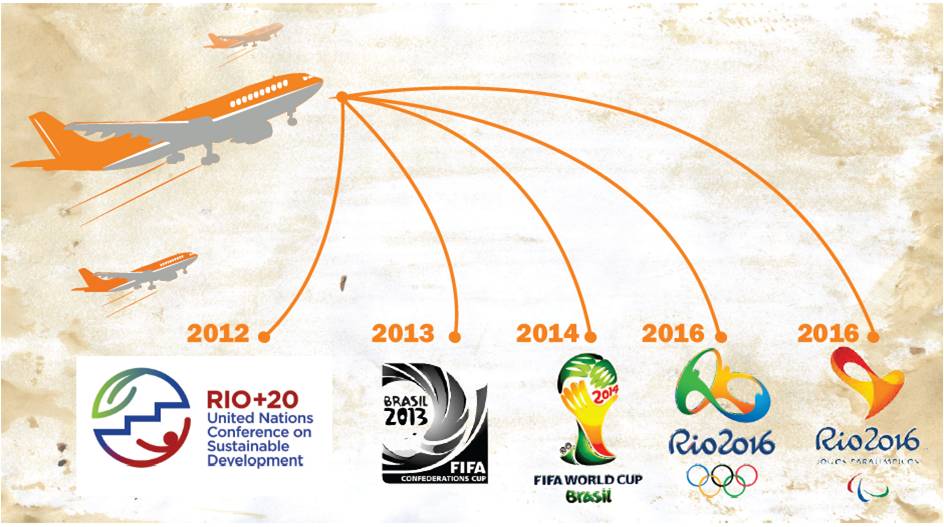

- Establish the Brazilian Biojetfuel Initiative as the private sector interface for US-Brazil Biojetfuel Bilateral Agreement. - Launch a "Flying Green" program to kick off a Carbon Footprint Offset Program for the Games: World Cup 2014, and Olympic Games 2016, establishing the necessary volume of neat required for the domestic flights of GOL, TAM, and Avianca, and infrastructure and logistics services required- SAB strategic planning for concerted bilateral actions of the private sector to implement pilot programs in the Americas.

- Establish a Pan American Biojetfuel Initiative based on the SAFUG Americas Chapter.

- Introduce through IICA the Green Economy Energy + Food Program in the Americas for sustainable biojetfuel feedstock production by intercropping Energy crops with short cycle cash crops.

The Flying Green Program is an excellent opportunity for private sector cooperation under the Brazilian Biojetfuel Platform to start the implementation of an integrated multifeedstock, multiprocess integrated value chain, leveraging on the branding opportunity of the 2014 World Cup. This integrated value chain includes FFP distribution at selected "green" airports.

The Brazilian Biojetfuel Platform was launched in 2010 by CURCAS as integrator, to structure the renewable feedstock segment, with a "from field to wing" integrated value chain, based on a multifeedstock and collaborative approach, to produce biojetfuel for the commercial aviation segment and renewable by-products for the chemical industry.

The case study for this incipient value chain was the consolidation of Jatropha curcas L. oil production from family farmers, and agribusiness in different regions of Brazil, its semi-refining in Barbacena, MG, and export to Houston, TX, where it was processed by UOP into biojetfuel for a successful demonstration flight of TAM Airlines in November 2010.

The Brazilian Biojetfuel Platform was launched in 2010 by CURCAS as integrator, to structure the renewable feedstock segment, with a "from field to wing" integrated value chain, based on a multifeedstock and collaborative approach, to produce biojetfuel for the commercial aviation segment and renewable by-products for the chemical industry.

The case study for this incipient value chain was the consolidation of Jatropha curcas L. oil production from family farmers, and agribusiness in different regions of Brazil, its semi-refining in Barbacena, MG, and export to Houston, TX, where it was processed by UOP into biojetfuel for a successful demonstration flight of TAM Airlines in November 2010.

The ASTM certification of the BioSPK on July 1st, 2011 gave birth to a new commodity market of 125 billion liters biojetfuel (based on IATA's Carbon Neutral Growth Program for up to 50% blending with fossil kerosene) by 2050. The available technologies today for the production of bioSPK will also offer a very interesting supply of renewable chemical products, namely C1/C5, biojetfuel, green diesel, biobutanol and green naphtha.

All available studies share the result that Brazil is the most promising area to establish a sustainable value chain for biorefinery products. Taking all key criteria into consideration, Brazil offers the most favorable assessment ratios ranging from availability of natural resources, climate conditions, infrastructure, public funding to political stability and support. These studies point out as well that the continuous availability of sustainable feedstock will be the main strategic challenge.

CURCAS, as the integrator of the Brazilian Biojetfuel Platform, is focused on harnessing this strategic challenge, making sustainable feedstocks available and organizing the biofuels distribution through off-take agreements with major logistic operators.

The Platform is considering a pilot project in the Southeastern Hub of Brazil, with the co-siting of a biorefinery unit at a major chemical site in the Paraiba Valley.

This biorefinery unit will produce biojetfuel to supply the major airports of Brazil (Congonhas, Guarulhos, Campinas, in the State of Sao Paulo, and Tom Jobim/Galeao and Santos Dumont in Rio de Janeiro), as well as renewable chemicals for the chemical industry and export.

While awaiting the scaling up of the major agricultural crops, the Platform at this initial stage will rely on the following supply chains:

a) Animal fat

b) Used cooking oil from Paraíba valley

c) Macaúba oil from natural maciços in Dores do Indaiá, Minas Gerais.

d) Jatropha oil from Minas Gerais, Espirito Santo, Sao Paulo, Rio de Janeiro and Parana

e) Camelina oil from the soy regions of Paraná, Mato Grosso, Mato Grosso do Sul and Rio Grande so Sul,

The segment of biokerosene is of strategic importance to the world in view of the its contribution to the mitigation of the GHG effects from the commercial aviation segment, which is responsible for 2% of the global emissions. IATA has established a Carbon Neutral Growth Program, where biojetfuel plays one of the most important roles to help achieve the carbon reduction goals. Furthermore Brazil and the United States have signed a specific bi-lateral biokerosene agreement, and the private sector, particularly the U.S. Chamber of Commerce, and Brazilian companies, is fully aligned in the process. The Platform will seek investors and U.S. companies, European, and Asian interest in the supply of sustainable feedstock for the global market for bio-jet fuels (Jatropha, Camelina, Macaúba, Babassu, Biomass) and other renewable products to replace fossil fuels as feedstock at chemical companies.

Curcas Diesel Brasil Ltda was founded in 2007 with the vision to address the development of a highly integrated and fully sustainable value chain to deliver bio-refined products in Brazil.

Curcas Diesel Brasil Ltda was founded in 2007 with the vision to address the development of a highly integrated and fully sustainable value chain to deliver bio-refined products in Brazil.

Curcas integrates all modules of the value chain from field to wing, developing and controlling feedstock, developing refinery capacities, selling and delivering bio-fuels to the end users under optimized logistics.

By integrating small farmers and agribusiness onto a new green economy value chain, sharing global research and development efforts, combined logistics efficiency, Curcas will help generate a new development cycle to reduce poverty in the communities engaged.

Curcas to operate across the value chain by bringing together stakeholders from the different segments onto a single value added platform for operating efficiency, developing sustainable feedstock, and integrated processing and logistics.

Curcas has retained experienced managers of diverse fields and backgrounds for the successful implementation of The Brazilian BioJetFuel Platform. This management is supported by stakeholders with high expertise in their specific fields and clear strategic view of the value chain.

Jan. 2007 founding of Curcas Diesel Brasil Ltda.

Sep. 2007 founding member of the ABPPM (Brazilian Association of Jatropha Producers).

May 2008 establishing a PPP Private Public Partnership with Embrapa Agroenergia for the domestication program of Jatropha in Brazil as well as other oil bearing plants.

Nov. 2009 launch of a Research and Development Platform during the I Brazilian Congress on Jatropha Research in Brasilia, D.F., with the support of the Brazilian Ministry of Agriculture.

Mar. 2010 launch of the Brazilian Biojetfuel Platform at WBM Amsterdam.

Nov. 2010 supply chain integrator of the first demonstration flight by TAM using biojetfuel from Jatropha in Brazil.

Mar. 2011 presentation of the Brazilian and launch of the Global Biojetfuel Platforms at the WBM in Amsterdam.

Nov. 2011 promotion of the II Congress on Jatropha Research in Brasilia, D.F. (with the support of the Brazilian Ministry of Agriculture), where the the state of the art in Jatropha domestication was made public.

Dec. 2011 promotion of the Workshop on Sustainability and Scalability of Jatropha Plantations in the Americas, to structure an Inter American effort, together with ABPPM and IICA, with the sponsorship of the InterAmerican Development Bank.

Jan. 2012 launch of the proprietary Flying Green Program.

Jun. 2012 supply chain integrator and promoter of the first biojetfuel flight by GOL in Brazil.

Aug. 2013 was structured the Brazilian Biojetfuel Platform as an open, collaborative, feedstock agnostic, multi-process platform bringing together key stakeholders for the implementation of a highly integrated bio-jet fuel and renewable value-chain in Brazil.

Oct. 2013 at the National day of Aviator, was the first commercial flight with Biojetfuel in Brazil promoted by GOL linhas Aereas Inteligentes under the new ANP 20 normative.

2013.11 Brazil Action Plan for reduction of GGE from aviation

2013.10.29 Press GOL 1º commercial flight in Brazil

2013.10.28 Press GOL 1º commercial flight

2012.06.19 Press Ambiente energia

2012.06.19 Press ICAO Communication

2012.06.19 Press G1 Globo News voo GOL

2012.06.19 Press OneWorld South Asia

IATA 2011 Report on Alternative Fuels

2013.09.18 WBM Brazil PBB- Curcas

2013.09.11 Plataforma Brasileira Bioquerosene-Ubrabio

2011.11.30 IICBPPM Curcas - Brasilia

2011.11.29 DCA ABPPM-Sao Jose dos Campos

2011.09.28 WBM ABPPM-Sao Paulo

2011.06.27 JWA ABPPM-Haikou China

2011.03.22 WBM ABPPM-Rotterdam

2010.08.17 V Seminario LATAM ABPPM-Santiago

An Information Technology based management system is being developed to cover the full value chain, using all of the resources of the web to integrate communities around the globe towards the common goals of the program, including the requirements to fulfill the sustainability compliance with regard to the RSB criteria.

The projected modules are:

* Data collection module - for the carbon footprint and productivity per Family Farmer and geo-referenced property, recording all required data for RSB compliance audit, and carbon footprint of the property.

* Image module - early detection of plagues and diseases, and control.

* Distance learning module - for digital inclusion, web based agricultural extension.

* Database - with historical series on climate, productivity, and sustainability.

The Pilot Data Collection module will be integrating product placement trials at Family Farmer's properties in Brazil, Mexico, and Colombia, using geo-referencing capable tablets, with exception reporting of the daily routines per property, and VoIP for direct communication.

Thereby a new paradigm will be implemented for a standard agricultural planning as well as agronomic procedures, dealing with Food+Energy programs, to guarantee Food security and Renewable Energy security.

In June 2007, the Steering Board of the Roundtable on Sustainable Biofuels (RSB) published draft principles for sustainable biofuels production, as the basis for a global stakeholder discussion around requirements for sustainable biofuels.

Interested stakeholders were invited to join a Working Group and suggest criteria for achieving these principles, as well as rewording for the draft principles themselves. After considerable stakeholder consultation the RSB released 'Version Zero' of the draft. Principles & Criteria for Sustainable Biofuels in August 2008 for a further six-month period of public consultation. From August 2008 to March 2009 in-person outreach meetings were held around the world in which biofuels stakeholders were invited to review and comment on the draft standard. In total, over 900 people participated in these in-person outreach events, and numerous more through email and other electronic means, contributing hundreds of comments and suggestions.

In January 2009 the RSB launched a new membership-based governance structure, in which stakeholders were invited to formally participate in the RSB through a chamber structure. Each chamber represents a different group of stakeholders interested in the promotion and use of sustainable biofuels. During 2009 further revisions to the draft RSB standard were discussed through several series of teleconference calls within the membership. A number of draft revisions were released throughout 2009, culminating in a meeting of the Steering Board in November 2009 in Lausanne, Switzerland to discuss approving the first full version of the standard (Version One). Based on pilot testing of Version One, a new round of public consultation (September 2010) and further discussions among RSB Chambers, Version 2 was approved by the RSB Steering Board on 5 November 2010.

Members may apply to participate in the chamber they feel best represents their organization, and after being approved by the RSB Steering Board, may participate in discussions regarding the content of the standard. Additionally, two representatives elected from each chamber serve on the Steering Board, the decision making body of the RSB. The Steering Board members represent the views of their chamber at the multi-stakeholder level, approve changes to the Principles & Criteria and other RSB documents, and are responsible for upholding the overall objectives of the RSB.

Criterion 1. Biofuel operations shall comply with all applicable laws and regulations of the country in which the operation occurs and with relevant international laws and agreements.

Operators who must comply: Feedstock Producer, Feedstock Processor, Biofuel Producer.

Criterion 2a. Biofuel operations shall undertake an impact assessment process to assess impacts and risks and ensure sustainability through the development of effective and efficient implementation, mitigation, monitoring and evaluation plans.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 2b. Free, Prior & Informed Consent (FPIC) shall form the basis for the process to be followed during all stakeholder consultation, which shall be gender sensitive and result in consensus-driven negotiated agreements.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 2c. Biofuel operators shall implement a business plan that reflects a commitment to long-term economic viability.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 3a. In geographic areas with legislative biofuel policy or regulations in force, in which biofuel must meet GHG reduction requirements across its lifecycle to comply with such policy or regulations and/or to qualify for certain incentives, biofuel operations subject to such policy or regulations shall comply with such policy and regulations and/or qualify for the applicable incentives.

Operators who must comply: Feedstock Producer, Feedstock Processor, Biofuel Producer, and Biofuel Blender.

Criterion 3b. Lifecycle GHG emissions of biofuel shall be calculated using the RSB lifecycle GHG emission calculation methodology, which incorporates methodological elements and input data from authoritative sources; is based on sound and accepted science; is updated periodically as new data become available; has system boundaries from Well to Wheel; includes GHG emissions from land use change, including, but not limited to above- and below-ground carbon stock changes; and incentivizes the use of co-products, residues and waste in such a way that the lifecycle GHG emissions of the biofuel are reduced.

Operators who must comply: Feedstock Producer, Feedstock Processor, Biofuel Producer, and Biofuel Blender.

Criterion 3c. Biofuel blends shall have on average 50% lower lifecycle greenhouse gas emissions relative to the fossil fuel baseline. Each biofuel in the blend shall have lower lifecycle GHG emissions than the fossil fuel baseline.

Operators who must comply: Biofuel Blender.

Criterion 4.a Workers shall enjoy freedom of association, the right to organize, and the right to collectively bargain.

Operators who must comply: Feedstock Producer, Feedstock Processor, and Biofuel Producer.

Criterion 4.b No slave labor or forced labor shall occur.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 4.c No child labor shall occur, except on family farms and then only when work does not interfere with the child's schooling and does not put his or her health at risk.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 4.d Workers shall be free of discrimination of any kind, whether in employment or opportunity, with respect to gender, wages, working conditions, and social benefits.

Operators who must comply: Feedstock Producer, Feedstock Processor, and Biofuel Producer.

Criterion 4e. Workers' wages and working conditions shall respect all applicable laws and international conventions, as well as all relevant collective agreements. Where a government regulated minimum wage is in place in a given country and applies to the specific industry sector, this shall be observed. Where a minimum wage is absent, the wage paid for a particular activity shall be negotiated and agreed on an annual basis with the worker. Men and women shall receive equal remuneration for work of equal value.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 4.f Conditions of occupational safety and health for workers shall follow internationally-recognized standards.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 4 g. Operators shall implement a mechanism to ensure the human rights and labor rights outlined in this principle apply equally when labor is contracted through third parties.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 5.a In regions of poverty, the socioeconomic status of local stakeholders impacted by biofuel operations shall be improved.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 5.b In regions of poverty, special measures that benefit and encourage the participation of women, youth, indigenous communities and the vulnerable in biofuel operations shall be designed and implemented.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer

Criterion 6a. Biofuel operations shall assess risks to food security in the region and locality and shall mitigate any negative impacts that result from biofuel operations.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 6b. In food insecure regions, biofuel operations shall enhance the local food security of the directly affected stakeholders.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer; smallscale operators are exempt.

Criterion 7.a Conservation values of local, regional or global importance within the potential or existing area of operation shall be maintained or enhanced.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 7.b Ecosystem functions and services that are directly affected by biofuel operations shall be maintained or enhanced.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 7.c Biofuel operations shall protect, restore or create buffer zones.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 7.d Ecological corridors shall be protected, restored or created to minimize fragmentation of habitats.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 7.e Biofuel operations shall prevent invasive species from invading areas outside the operation site.

Operators who must comply: Feedstock Producer and Feedstock Processo

Criterion 8.a Operators shall implement practices to maintain or enhance soil physical, chemical, and biological conditions.

Operators who must comply: Feedstock Producer.

Criterion 9.a Biofuel operations shall respect the existing water rights of local and indigenous communities.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 9.b Biofuel operations shall include a water management plan which aims to use water efficiently and to maintain or enhance the quality of the water resources that are used for biofuel operations.

Operators who must comply: Feedstock Producer, Feedstock Processor, and Biofuel Producer.

Criterion 9.c Biofuel operations shall not contribute to the depletion of surface or groundwater resources beyond replenishment capacities.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 9.d Biofuel operations shall contribute to the enhancement or maintaining of the quality of the surface and groundwater resources.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 10.a Air pollution emission sources from biofuel operations shall be identified, and air pollutant emissions minimized through an air management plan.

Operators who must comply: Feedstock Processor and Biofuel Producer.

Criterion 10.b Biofuel operations shall avoid and, where possible, eliminate open-air burning of residues, wastes or by-products, or open air burning to clear the land.

Operators who must comply: Feedstock Producer, Feedstock Processor.

Criterion 11.a Information on the use of technologies in biofuel operations shall be fully available, unless limited by national law or international agreements on intellectual property.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 11.b The technologies used in biofuel operations including genetically modified: plants, micro-organisms, and algae, shall minimize the risk of damages to environment and people, and improve environmental and/or social performance over the long term.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 11.c Micro-organisms used in biofuel operations which may represent a risk to the environment or people shall be adequately contained to prevent release into the environment.

Operators who must comply: Feedstock producer, Feedstock processor, and Biofuel Producer.

Criterion 11.d Good practices shall be implemented for the storage, handling, use, and disposal of biofuels and chemicals.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

Criterion 11.e Residues, wastes and byproducts from feedstock processing and biofuel production units shall be managed such that soil, water and air physical, chemical, and biological conditions are not damaged.

Operators who must comply: Feedstock Processor and Biofuel Producer.

Criterion 12.a Existing land rights and land use rights, both formal and informal, shall be assessed, documented, and established. The right to use land for biofuel operations shall be established only when these rights are determined.

Operators who must comply: Feedstock Producer and Feedstock Processor.

Criterion 12.b Free, Prior, and Informed Consent shall form the basis for all negotiated agreements for any compensation, acquisition, or voluntary relinquishment of rights by land users or owners for biofuel operations.

Operators who must comply: Feedstock Producer, Feedstock Processor and Biofuel Producer.

The agroclimatic map for the State of Espírito Santo is being developed together with INCAPER and the State Secretary of Agriculture to define suitable areas for Jatropha, within the Polo do Pinhão Manso.The agricultural production will be integrated into the Fusermann crushing and semi-refining plant in Barbacena, MG with certification of a semi-refined Jatropha value chain for export of feedstock through the Port of Rio de Janeiro or Vitoria.

The agroclimatic map for the State of Espírito Santo is being developed together with INCAPER and the State Secretary of Agriculture to define suitable areas for Jatropha, within the Polo do Pinhão Manso.The agricultural production will be integrated into the Fusermann crushing and semi-refining plant in Barbacena, MG with certification of a semi-refined Jatropha value chain for export of feedstock through the Port of Rio de Janeiro or Vitoria.

Additionally Jatropha is being planted in the Londrina region, and will be leveraging on the soy and camelina supply chain.

The implementation of camelina as feedstock for biofuels as a rotation and winter crop in soy bean fields in Brazil, is part of the multiple feedstock strategy underway. Research institutions supporting the introduction of Camelina in Parana are Embrapa Soja and Universidade Estadual de Londrina.

The implementation of camelina as feedstock for biofuels as a rotation and winter crop in soy bean fields in Brazil, is part of the multiple feedstock strategy underway. Research institutions supporting the introduction of Camelina in Parana are Embrapa Soja and Universidade Estadual de Londrina.

(Orbignya phalerata, Mart.) – Brazil's north-northeastern region has more than 18 million hectares of native Babaçu forests that present an excellent opportunity for sustainable exploration of the full kernel and social inclusion of local communities.

(Acrocomia aculeata.) – Brazil's central region has native Macaúba maciços that present an excellent opportunity for sustainable exploration of the full kernel and social inclusion of local communities.

In Brazil there are several resources which could be used as feedstock for a biorefinery. At first Curcas is looking at used cooking oil and industrial bio waste. Curcas is working at integrating these product flows into the Biokerosene Platform as base load.

In Brazil there are several resources which could be used as feedstock for a biorefinery. At first Curcas is looking at used cooking oil and industrial bio waste. Curcas is working at integrating these product flows into the Biokerosene Platform as base load.

In Brazil currently the edible vegetable oil production is in the range of 4 bn liters/ year. Of this less than 1% is currently being recycled in spite of some few collecting cooperatives in major cities. Used cooking oil is presently disposed of mainly in the sewage system and its neutralization is a major cost factor for water recycling. The inadequate discharging of used oil also can be a major contaminant of clean water.

Curcas is structuring a PPP – Public Private Partnership for a Going Green Initiative.

Offtake agreements with meat processors will guarantee a base-load of feedstock for the hydroprocessing.

The Flying Green Program is being established by Curcas, as the integrator, to provide the framework for the business community to take concrete actions to support multi-feedstock biojetfuel projects in different countries by bringing together interested stakeholders, investors, governments, NGOs, financial institutions to build a green economy for the biojetfuel segment.

The Flying Green Program is being established by Curcas, as the integrator, to provide the framework for the business community to take concrete actions to support multi-feedstock biojetfuel projects in different countries by bringing together interested stakeholders, investors, governments, NGOs, financial institutions to build a green economy for the biojetfuel segment.

Since biofuel production technology has not been the problem but the availability of sustainable non-food biomass feedstock, Curcas is engineering the program as a global collaborative effort towards achieving Millenium Development Goals in this UN International Year of Sustainable Energy for All .

The Flying Green Program will focus on:

1. Establishing a sponsorship and funding program to catalyse the implementation of certified multi-feedstock biojet fuel value chains in different countries to provide biojetfuel for "green flights" to and within Brazil during the major international sports events in the period of 2012-2020. Interested stakeholders, governments, corporations, individuals are invited to sign-up for sponsorship to support sustainable actions in the seven continents to address the challenge of producing sustainable feedstock and establishing a renewable biojetfuel pool to fuel the flights, while reducing poverty.

2. Establishing a sustainable feedstock pool from the participating value chains to feed into biorefineries , for the optimal planning, production and distribution of biojetfuel to the selected flights.

3. Establishing "from field to wing" pilot value chains , integrating small farmers and agribusiness onto a new green economy value chain, sharing global research and development efforts, combined logistics efficiency, to generate a new development cycle to reduce poverty in the communities engaged.

4. Establishing a public awareness during these international sporting events on the contribution of biojetfuels towards the mitigation of GHG effects.

5. Establishing an IT-based management system for the global value chain.

The formal kick-off of was at the RIO+20 (UN Conference on Sustainable Development) event in Rio de Janeiro, Brazil June 19th 2012. First milestone is at the Confederations Cup 2013 followed by the World Cup 2014, the 2016 Summer Olympics and 2016 Paralympics in Rio de Janeiro / Brazil.

Production facilities:

A multifeedstock biorefinery is being planned for the Southeastern Hub within a major chemical complex in the Vale do Paraiba, Sao Paulo. This co-siting alternative will reduce CAPEX and time to market, and will also leverage on existing rail facilities at the chemical plant for inbound combined feedstock, and export of renewable chemicals through the Port of Santos in Sao Paulo.

The biorefinery will have a start up nominal plant capacity of 100.000 t/yr, to be implemented by 2014. Additional plant expansion capacity to 250.000 t/yr planned for commissioning in 2017/2018.

We, the undersigned, joined by the common will to promote a sustainable environment for the future generations, embrace and endorse the global efforts towards building a Green Economy based on the Biojetfuel and Renewable chemicals segment.

Aviation is one of the strongest growing transport sectors. In the period up to 2050, worldwide aviation is expected to grow by 4.5% annually. If fuel consumption and CO2 emissions were to grow at the same rate, CO2 emissions by worldwide aviation in 2050 would be nearly six times their current figure.

Historically, significant fuel efficiency gains have been achieved by operational improvements (e.g. higher load factors, utilization of larger aircraft) and by technical progress (e.g. more efficient engines, lighter airframes). This is expected to continue. As a consequence, aviation fuel consumption is forecast to grow only by 3% annually. Even this, however, implies a more than tripling of CO2 emissions by 2050.

Aviation growth rates are expected to be highest in strongly developing countries, particularly Asia, and lower in regions where aviation is already well developed. For the EU, aviation traffic expected to grow at an average rate of 3% annually until 2050, implying fuel consumption growth of 2% annually, and hence a more than doubling of CO2 emissions by 2050.

In awareness of the environmental consequences of continued CO2 growth, IATA members have pledged the following goals:

• Improve fuel efficiency by 1.5% per year during the subsequent decade

• Make all industry growth carbon-neutral by 2020

• Reduce net CO2 emissions by 50% by 2050, compared with 2005 levels

The Global Biojetfuel Initiative was first conceived by ABPPM, Jatropha Alliance, CURCAS, COSMO and presented to IATA in March, 2010 at the WBM – World Biofuel Markets in Amsterdam, to establish a collaborative AAA platform, uniting actions in the three continents: Americas, Africa, Asia to meet the sustainable feedstock challenge for the Carbon Neutral Growth program of IATA.

We launch at RIO+20, our commitment being to structure the Global Biojetfuel Initiative as a first step towards a Green Economy to stitch together, using the golden thread, an open collaborative platform. It is intended to bring together governments, farmers, associations,research institutions, non-governmental organizations, stakeholders, related downstream chemical companies, and users of air transportation, to promote integrated actions towards a global sustainable biojetfuel and renewable chemicals value chain. An executive committee will be formed in the subsequent steps, with the vision of structuring a global fund to promote integrated R&D efforts for sustainable feedstocks, similar to the Pan-American Research Platform on Jatropha coordinated by IICA. This committee will select pilot projects in the different continents for coordinated trials, as well as consolidating sustainable feedstock worldwide to promote commercial flights using biojetfuel.

The concurrent launch of the Brazilian Biojetfuel Platform by UBRABIO at RIO+20 will establish the first step of the Americas' engagement towards the goals of the Global Biojetfuel Initiative. A Flying Green, Riding Green Program will be launched to promote commercial flights with biojetfuel for the 2014 FIFA World Cup, and 2016 Summer Olympics in Brazil.

Based on published emissions estimates from the 2008 Beijing Summer Olympics and the 2010 FIFA World Cup in South Africa, it is estimated that between 3 and 3.5 million tones of additional CO2 emissions from aviation may be generated because of the two events in Brazil.

Contributing to reduce these emissions, the Brazilian Biojetfuel Platform proposes a "Flying Green"towards an Aviation Carbon-Neutral 2014 FIFA World Cup and 2016 Summer Olympics for educating the public about what can be achieved in reducing carbon emissions and by engaging the public in the effort to create a sustainable world. The aim being that all flights to and from Brazil and within Brazil should be supplied with a biojetfuel content. Additionally a "Riding Green" program for the ground fleet will call for a minimum of B20 biodiesel blend for the public transportation fleet during these events.

It is a global call for action and collaboration towards a unique Green Economy program, reasserting the positive agenda: Join the Global Initiative, and show to the world your project or personal effort!